When you use InnControl™ from Innkeeper LLC, you get more than just a reliable, affordable control system. You get a complete solution that combines powerful machine controls and built-in data acquisition through integration with MicroMaster. But what exactly is MicroMaster and how can this technology be beneficial for you?

What is MicroMaster?

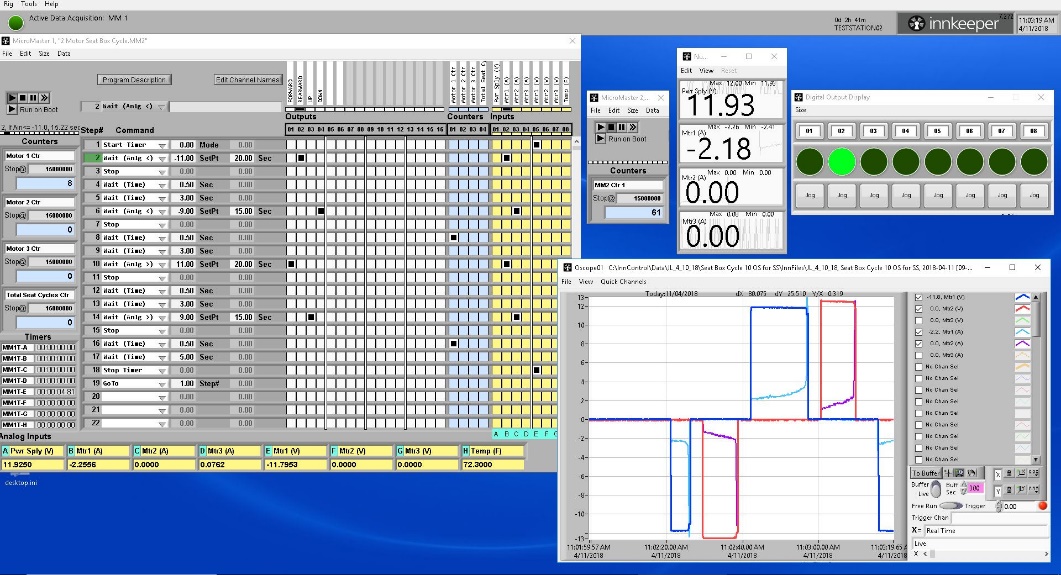

MicroMaster is a sequential logic controller which runs within the InnControl platform and handles Life Cycle durability testing, displaying and acquiring data on demand with the ability to save programs and recall them for later use. InnControl™ with MicroMaster has the ability to work with devices like pneumatic valves, motors, solenoids, and relays commonly used to control tests for automotive, aerospace and biomedical components. MicroMaster uses feedback from all sorts of components to create easily programmable yet comprehensive test sequences using live displacement, force, temperature, current, voltage, acceleration, switch closure, counters…

MicroMaster units are readily available in Standard Manual and Standard Power options, but virtually any hardware configuration can be provided. Standard Manual units control against time, count, limit switches, force, torque, displacement, and angle. Standard Power units also control against time, count, and limit switches, but also against voltage and current.

Benefits of InnControl MicroMaster

MicroMaster is a simple and flexible solution that delivers the functionality and power to meet the needs of a wide range of testing functions. InnControl with MicroMaster can be applied to nearly any test function and can conduct multiple individual tests simultaneously from a single controller, preventing you from having to spend money on systems that only serve a single purpose. There’s no limit to the number of control channels or inputs that can be used. With a standard interface, you’ll be able to collect all this data while reducing test setup time.

Standard configuration of the Manual and Power Durability Systems include these items, yet it can be configured to the customer’s requirements.

- 8 digital outputs

- 2 analog outputs

- 8 analog inputs

- 4 digital inputs

High resolution and flexible data acquisition are key advantages. All analog inputs/outputs have 16-bit resolution with 100hz sample time, up to 1000hz possible as standard. A High Speed option is available for up to 10,000hz. Adjustable acquisition rates are possible between the sample rate down to 1 single data point with this system, which is something you otherwise wouldn’t be able to do without separate external acquisition systems.

Another reason why MicroMaster is so highly functional is because of its ability to control components using several different communication standards, including digital I/O, LIN, CAN, MODBUS, and TCP/IP.

Need to move a test sequence to another MicroMaster control unit? No problem. These systems are designed to allow for seamless sequence program transfers between the controllers.

Get Started With MicroMaster

Ready to start taking advantage of all the benefits MicroMaster has to offer? Innkeeper makes it easy to get the durability test equipment controllers you need. Options include:

- Direct purchase controllers

- Rent them on a month-to-month basis, or

- Purchase them through rent-to-own agreements.

Contact us today to get started.